Screw plug gauges are precision tools used to check the pitch diameter, major diameter, and minor diameter of threaded holes. Calibration ensures these gauges provide accurate measurements, which is critical for ensuring that threaded components fit correctly. Regular calibration ensures that the measurements taken by the screw plug gauges remain consistent over time, which is crucial for maintaining product quality and ensuring that components are interchangeable.

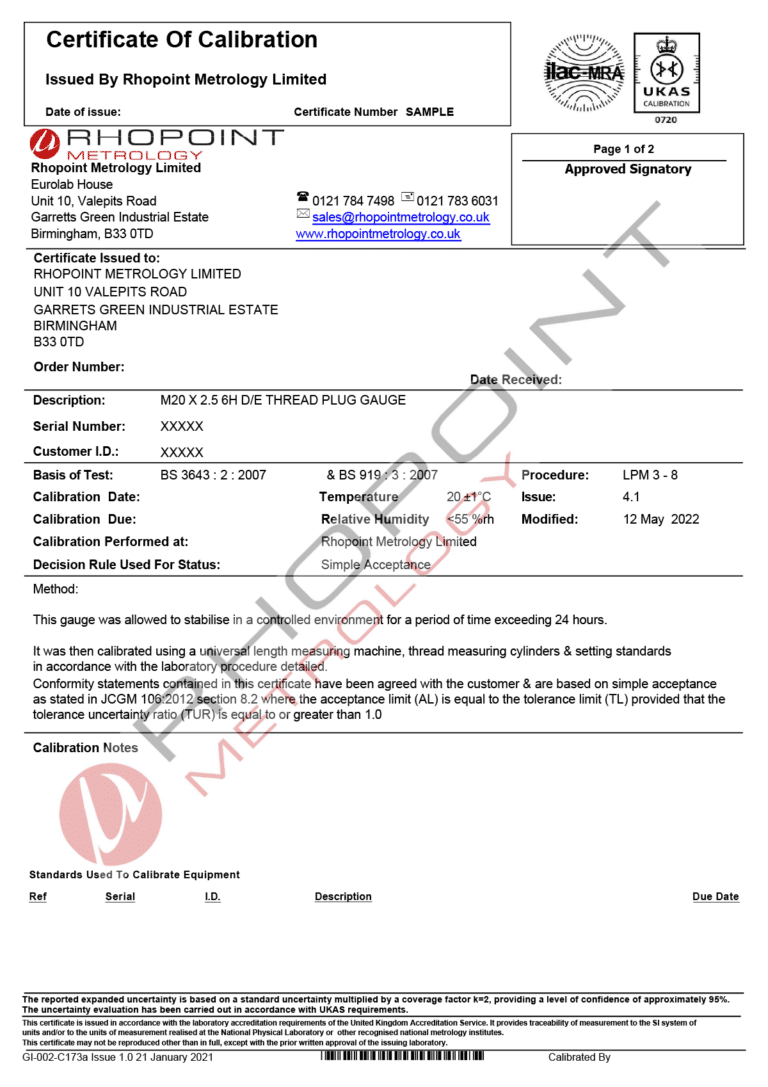

Rhopoint Metrology offers ISO 17025 UKAS certified calibration for screw plug gauges. With years of experience in the field and our specialized knowledge ensures a thorough and precise calibration process.

Our services are available onsite and at our laboratories in Birmingham and Bristol. Enquire now for pricing.

Thread Plug GaugesTo Top | ||||

| UKAS Calibration for Screw Plug – Parallel – Single Ended – up to 100 mm (up to 4″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Single Ended – 100 – 150 mm (4 – 6″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Single Ended – 150 – 250 mm (6 – 10″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Single Ended – above 250 mm (above 10″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Double Ended – up to 100 mm (up to 4″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Double Ended – 100 – 150 mm (4 – 6″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Double Ended – 150 – 250 mm (6 – 10″) | UKAS | Add to Quote | ||

| UKAS Calibration for Screw Plug – Parallel – Double Ended – above 250 mm (above 10″) | UKAS | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Taper – up to 50 mm (up to 2″) | UKAS | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Taper – above 50 mm (Above 2″) | UKAS | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Trapezoidal / Acme – up to 50 mm (up to 2″) | UKAS | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Trapezoidal / Acme – 50 up to 150mm (above 2″ – 6″) | UKAS | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Trapezoidal / Acme – 150 up to 250mm (over 6 up to 10″) | UKAS | Add to Quote | ||

| Traceable Calibration for Screw Plug Gauge – Line Pipe – up to 25mm (Up to 1″) | Traceable | Add to Quote | ||

| Traceable Calibration for Screw Plug Gauge – Line Pipe – 25mm – 50mm (From 1 – 2″) | Traceable | Add to Quote | ||

| Traceable Calibration for Screw Plug Gauge – Line Pipe – 50mm – 100mm (From 2 – 4″) | Traceable | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Buttress – up to 50 mm (up to 2″) | UKAS | Add to Quote | ||

| UKAS Calibration for Plug Gauges – Threaded (Screw Plugs) – Buttress – above 50 mm (above 2″) | UKAS | Add to Quote | ||

If you haven’t found the calibration you require or need some further assistance with your requirement, contact us using this form and we can find the solution you are looking for.

To ensure we can promptly address your calibration enquiry, please complete the form with all the necessary details. This will help us to provide you with accurate and timely assistance.

For urgent enquiries, please contact us directly via phone at:

Theses standards specify the tolerances and limits for simple forms of thread gauges, such as:

Parallel thread plug gauges

Parallel thread ring gauges

It is highly recommended that an appropriate authority such as a UKAS approved laboratory carries out a full calibration on thread gauges at least once a year. In between UKAS calibrations at a frequency based on usage, thread gauges should be calibrated in-house. A typical in-house calibration would include a written procedure and an associated calibration record sheet, which would contain as a minimum, the following listed information:

(a) Serial number

(b) Location

(c) Procedure number

(d) Rate and compression correction

(e) Gauge tolerance

(f) Results

(g) Measurement uncertainty

(h) Sentence if appropriate

(i) Date and calibrators signature

(j) Traceability to National Standards

It is necessary that any person carrying out such calibration work should have received appropriate training and have shown the ability to be confident via a suitable training authority. Training records should be held and maintained.

Following are layouts for typical in-house calibrations for thread gauges:

Calibration to be carried out in accordance with in-house procedure number …………………..

Serial Number: Make:

Calibration Date: Sizes:

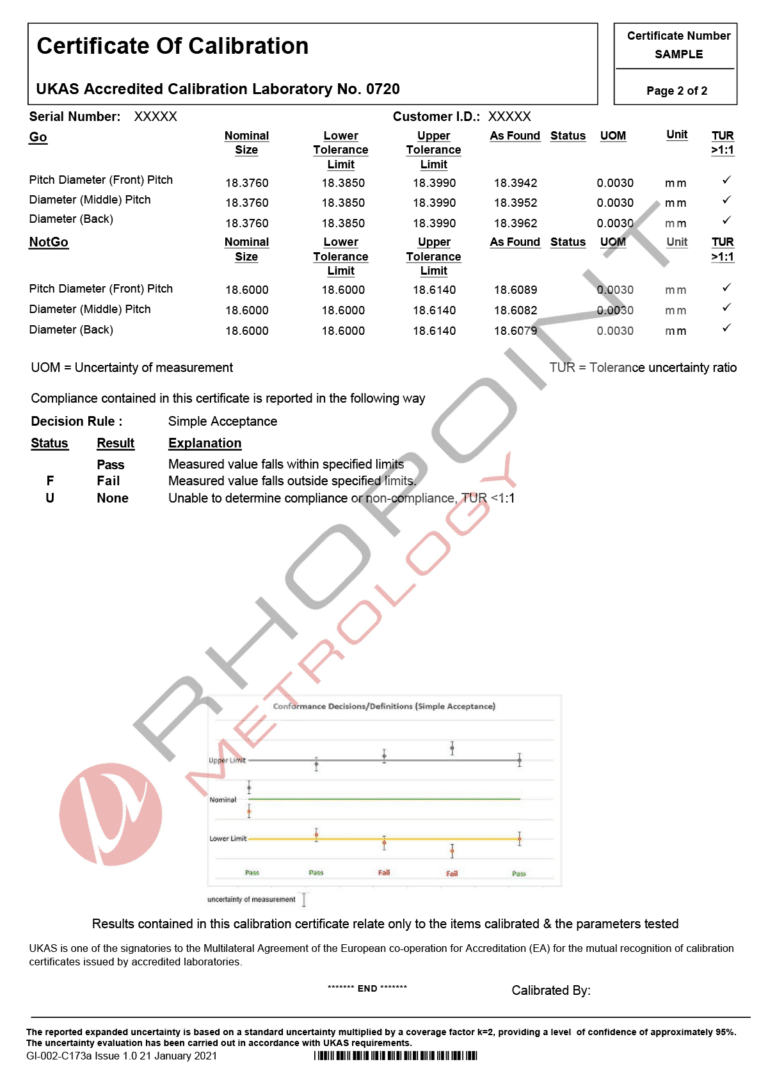

FEATURE EXAMINED SPEC. MEASURED RESULTS

GO:

Major diameter

Pitch diameter

Minor diameter

NOT GO:

Major diameter

Pitch diameter

Minor diameter

(Go and NOT go are measured at the front, middle and back of the thread)

The thread gauges were visually inspected for damage and the following faults were noted:

MEASUREMENT UNCERTAINTY +/- 0.003mm (1-100mm range)

Source: UKAS schedule of accreditation, Calibration and measurement capability (CMC)

Calibrators Signature: ………………………………….

A traceability statement in this section would be required for all items and their relevant certification utilised for the calibration of thread gauges.

Below is a layout for a typical in-house calibration for a screw plug gauge.

All of our Laboratories are accredited to provide UKAS & Traceable calibrations to all the relevant standards giving you peace of mind.

Make consistent, accurate and reliable measurements

Ensure longevity of the measuring instruments

Ensure safety in critical applications such as medical and aerospace

Rhopoint Metrology Ltd Eurolab House, Unit 10 Valepits Road, Garretts Green Industrial Estate, Birmingham, B33 0TD

Rhopoint Metrology Ltd Brunel House, 28 Old Mills Industrial Estate, Paulton, BS39 7SU